When it comes to designing a supermarket, there are many factors to consider, including the layout, shelving systems, lighting, and overall aesthetics. One crucial aspect of supermarket design that is often overlooked is the width of the aisles. Aisle width refers to the space between the shelves that customers use to navigate through the store.…

Read MoreAt TPT, we know the value of the Lean Six Sigma methodology for improving business processes, reducing waste, and increasing efficiency. Lean Six Sigma certifications are measured in levels represented by belts similar to different forms of martial arts. This makes the first level the Lean Six Sigma White Belt. What is a Lean Six…

Read MoreIndustrial operations can be complex and challenging to manage. With increasing competition, rising costs, and evolving customer demands, organizations need to continually evaluate and improve their processes to stay ahead. A lean assessment can help organizations achieve operational excellence by identifying inefficiencies, reducing waste, and improving quality. What is a Lean Assessment? A lean assessment…

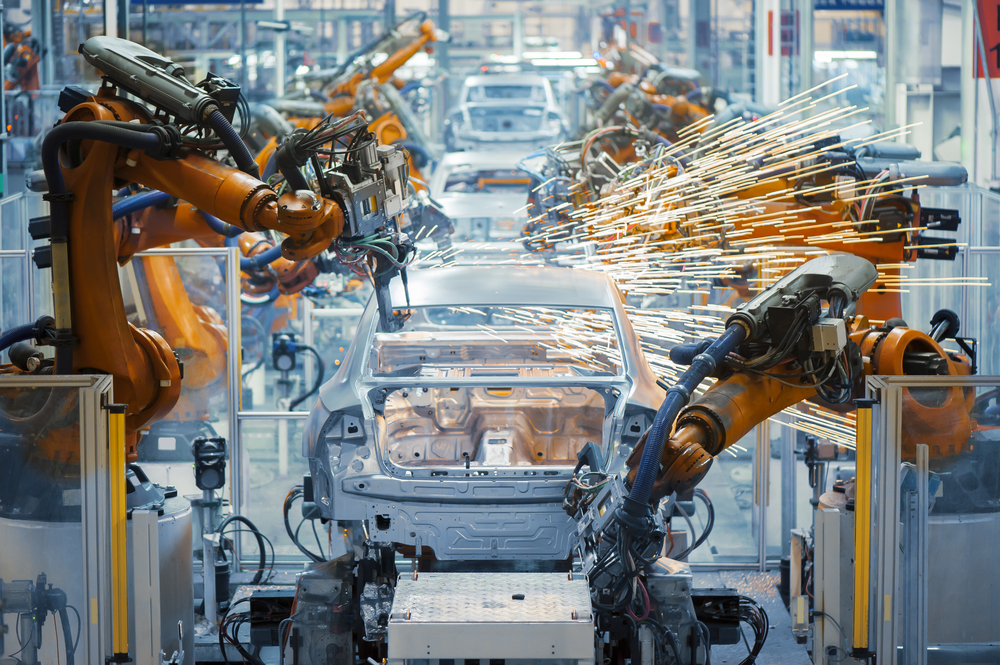

Read MoreManufacturing is a complex and challenging industry that requires careful planning and execution. Running a factory involves a lot of moving parts, from sourcing raw materials to delivering finished products, and it can be difficult to make decisions that will improve your bottom line. But, what if we told you there’s a solution to help…

Read MoreIn the fast-paced world of production, every minute counts. And when your processes are bogged down by inefficiencies and delays, it can be frustrating and costly. That’s where process engineering comes in. This specialized field of engineering focuses on optimizing production processes to increase speed, improve quality, and enhance safety, ultimately leading to increased profitability.…

Read MoreDo you find it challenging to manage multiple manufacturing facilities? Facility consolidation can streamline the process and offers many benefits to your organization. In this article, we will explore what facility consolidation is, the advantages that come with it, the best practices when implementing consolidation, and where to find top-notch consolidated facility services. What is…

Read MoreSupply chain management is a critical aspect of any manufacturing business. Having an efficient and well-organized supply chain can make a big difference in the success of the organization. PFEP, or Plan For Every Part, is one tool that can help businesses optimize their supply chain. Read on to learn about PFEP and its benefits.…

Read MoreToday’s fast-paced, intricate goods manufacturing industry wouldn’t be where it is without some smart logistics. In this article, we’ll explore one of these techniques – kitting – and how kitting operations can be used to improve the efficiency of product shipments. What Is Kitting? Kitting is a technique used in logistics to simplify and streamline…

Read MoreWant a more productive and cost-efficient manufacturing process? With process improvement services like line balancing, you can level the workload across different processes in a value stream to mitigate excess capacity and bottlenecks. To achieve manufacturing optimization, you need a fast production rate, reduce waiting waste, and minimize downtime. That’s where line balancing can help.…

Read MoreIn any manufacturing setting, it’s crucial to have a well-oiled machine — quite literally. Every piece of the manufacturing process must work in tandem to create the final product. Unfortunately, manufacturing is a complex process with many potential points of failure. If one cog in the wheel is missing or broken, the entire process can…

Read More