What is Time Study?

According to the British Standard Institute, time study/work measurement has been defined as:

“The application of techniques designed to establish the time for a qualified worker to carry out a specified job at a defined level of performance.”

What is MODAPTS?

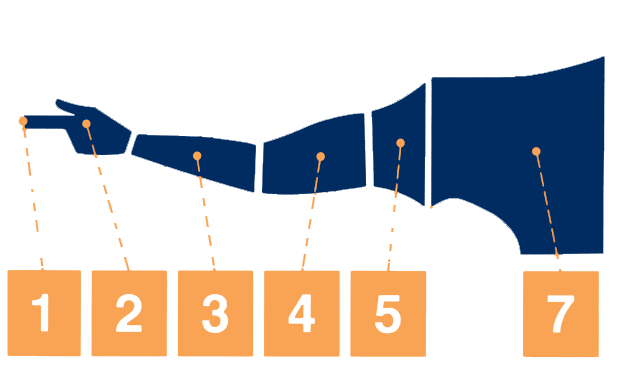

MODAPTS or modular arrangement of predetermined time standards, is a simple and descriptive language for understanding work, tasks, or activities. All MODAPTS times are multiples of 0.129 seconds.

MODAPTS is a form of shorthand or a succinct language for describing the sequence of body actions involved in carrying out particular work.

Unlike the MTM and MOST standards, MODAPTS uses a MOD as its basic unit of measurement (1 MOD = 0.129 seconds). However, like Basic-MOST, MODAPTS uses a coding technique that consists of a letter and an integer number (all but 1 code), where the integer numbers each represent MODS that can be easily added to determine a coded task’s time.

The Productivity Team is uniquely positioned as the Engineering Servicing Company with the largest amount of MODAPTS (modular arrangement of predetermined time studies) certified Engineers in the United States. Our team of MODAPTS certified engineers have decades of combined experience using the process to immediately improve any operational productivity, calculate reliable production standards, and analyze departmental efficiency objectively.

Benefits of MODAPTS Labor Optimization

MODAPTS is commonly used by companies to get an accurate assessment of their current state of direct and indirect labor times to conduct daily tasks to complete work assignments. By using a predetermined time study tool such as MODAPTS, industrial engineers are able to conduct accurate time studies using video recording.

This saves time and expense to the end-user because the industrial engineers do not have to be on-site to complete a time study.

Understanding what employees do, how they do them, how long it takes them to do them, how often, with what tools, in what space, for what product, and therefore at what cost.

A comprehensive evaluation allows manufacturing firms to understand the true costs associated with unit production.

With a comprehensive understanding of every task involved in each manufacturing position, MODAPTS provides a framework to quickly identify areas of improvement through the development of standards. Once standards have been identified, manufacturing firms have indisputable knowledge that their production facilities are maximizing labor resources and working at the highest efficiency.

Some ways this is accomplished is through the elimination of unnecessary, time-intensive duties, consolidation of repetitive tasks, and implementation of efficiency-minded, employee-centric work environments; all of which translates to higher quality products.

With the knowledge that the manufacturing production flow is running as efficiently as possible while utilizing the least amount of resources, manufacturing firms can take on new challenges, grow new capabilities, and improve production without additional employees. With these savings, manufactures can expand and improve their products to be increasingly competitive in their industries.

With improved production and growing capabilities, change is not only expected but is also desirable. As the manufacturer continues to meet changing client expectations over time, it is crucial to constantly strive for the highest level of efficiency possible. As with all predetermined time standard systems, MODAPTS standards are living documents that need to be maintained in order to continuously provide benefits.

MODAPTS time studies excels because its fast, consistent, and easy to learn. If maintained, manufacturing firms will continue to have the benefits that MODAPTS provides without having to spend excessive time and money to maintain accurate information.

The TPT Difference

For most of our clients, we send in qualified industrial engineers to videotape the operations and work elements that are to be studied. We do the actual MODAPTS coding at our office which saves time, money, and does not disrupt the manufacturing and assembly process or throughput at our client’s facilities.

Our proprietary spreadsheets and reporting tools are developed so our clients are left with data that they can use to further improve their productivity. All that is required is scheduling a meeting at our client’s facility to review their goals, expectations, and timing for the end deliverable.

We can support your MODAPTS needs through:

TPT has been providing MODAPTS time study services to Ford Motor, FCA and numerous automotive Tier 1 suppliers for over 16 years. From non-profits that employ individuals with disabilities to major manufacturers such as Ford, Chrysler, Johnson Controls, and G.E., MODAPTS can be utilized by anyone needing to set an accurate production rate.