Optimizations

Professional Manufacturing and Supply Chain Consulting Services

Our supply chain optimization consulting services play a crucial role in optimizing the engineering, pricing, design, and operations of supply chains. These services offer specialized expertise to enhance the efficiency and effectiveness of supply chain processes. Through a holistic approach that integrates design with operational considerations, supply chain consulting services help organizations achieve sustainable growth…

Read MoreMaximize Productivity and Reduce Costs with Labor Optimization Services from TPT

In today’s competitive business landscape, maximizing productivity and reducing costs are key priorities for any organization. That’s where labor optimization services from TPT can make a significant impact. By leveraging cutting-edge engineering techniques and expertise, TPT helps businesses streamline their workforce management processes to achieve optimal efficiency. Our MODAPTS Certified Engineers MODAPTS, or modular arrangement…

Read MoreMaintain Control of Your Materials with The Productivity Team’s MP&L Services

In today’s fast-paced business environment, effective supply chain management is crucial. At The Productivity Team, we specialize in Materials Planning and Logistics (MP&L) services, essential for operational efficiency and customer satisfaction. Our MP&L services provide comprehensive solutions to optimize material handling and logistics operations. Streamlining Inventory and Logistics Management Our approach to inventory management balances…

Read MoreCreate A Plan to Handle, Store, Replenish, and Transport Your Materials with PFEP Development

To effectively handle, store, replenish, and transport your materials, it is crucial to develop a Plan for Every Part (PFEP). PFEP development is a strategic approach that allows businesses to optimize their material flow and minimize waste throughout the supply chain. Know Your Parts The first step in PFEP development is to thoroughly analyze your…

Read MoreThe Various Steps of Lean Facility Layout Development

Lean facility layout development involves a series of steps that are crucial for optimizing efficiency and productivity. By carefully analyzing current processes, identifying opportunities for improvement, designing the new layout, implementing changes, and continuously reviewing and refining, businesses can create an environment that maximizes workflow and minimizes waste. Step 1: What Are You Currently Doing?…

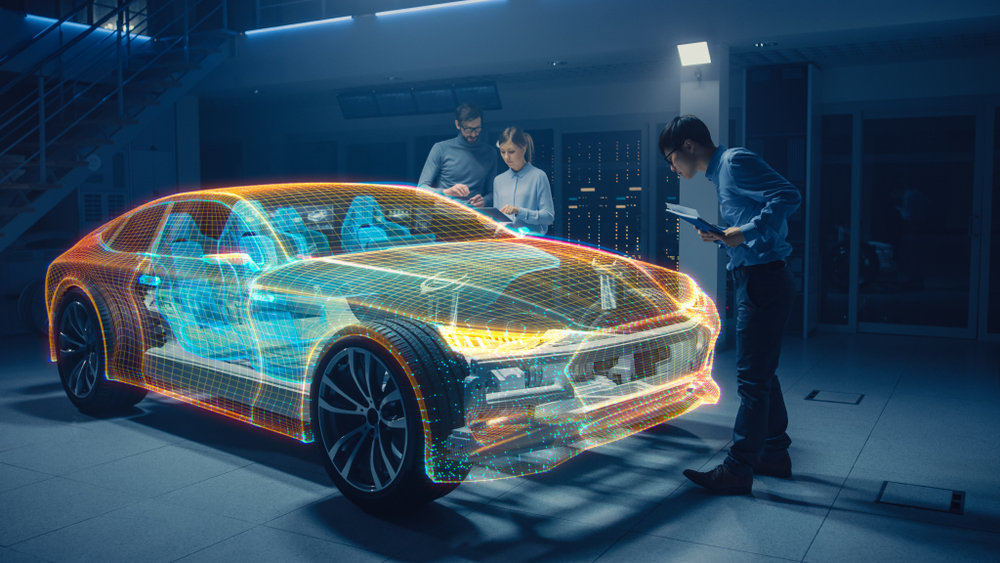

Read MoreDriving Efficiency: How Automotive Engineering Services Optimize Vehicle Performance

Automotive engineering services are essential in optimizing vehicle performance, encompassing a range of activities from design and engineering to testing and validation, aimed at enhancing various aspects of a vehicle’s functionality. Design and Development In the design and development phase, engineers focus on aerodynamics to reduce drag and improve fuel efficiency. They employ lightweight materials…

Read MoreLean Manufacturing Optimization: Improve Efficiency with Lean Principles

Manufacturing optimization is a journey that leads to improved efficiency, reduced waste, and increased profitability. One approach that has proven successful in this journey is lean manufacturing. Lean principles focus on creating more value for customers with fewer resources, driving manufacturing optimization by eliminating non-value-added activities. In this article, we delve into how lean manufacturing…

Read MoreThe Impact of Engineering Staffing on Product Development Cycles

Engineering, a key driver of innovation and technology, is heavily reliant on human expertise and talent. Within the realm of product development, the dynamics and quality of engineering staffing play a significant role in determining the efficiency and success of development cycles. Strategic staffing decisions can make or break a product’s journey from conception to…

Read MoreHow Overall Equipment Effectiveness (OEE) Kickstarts Root Cause Failure Analysis (RCFA)

Overall Equipment Effectiveness (OEE) plays a pivotal role in instigating root cause failure analysis (RCFA) in manufacturing and production facilities. OEE is a standardized metric that evaluates how effectively a manufacturing operation is utilized, considering factors such as performance, quality, and availability. By meticulously analyzing these aspects, OEE provides a broad spectrum of insights into…

Read MoreThe Power of the 3P Process in Lean Layout Development

The world of manufacturing constantly seeks to improve, to evolve, and to fine-tune its processes. Central to this evolution is the 3P Process or the Production Preparation Process. This approach has revolutionized the way products are designed and developed, ensuring a leaner, more efficient manufacturing process. Understanding the 3P Process At its core, the 3P…

Read More